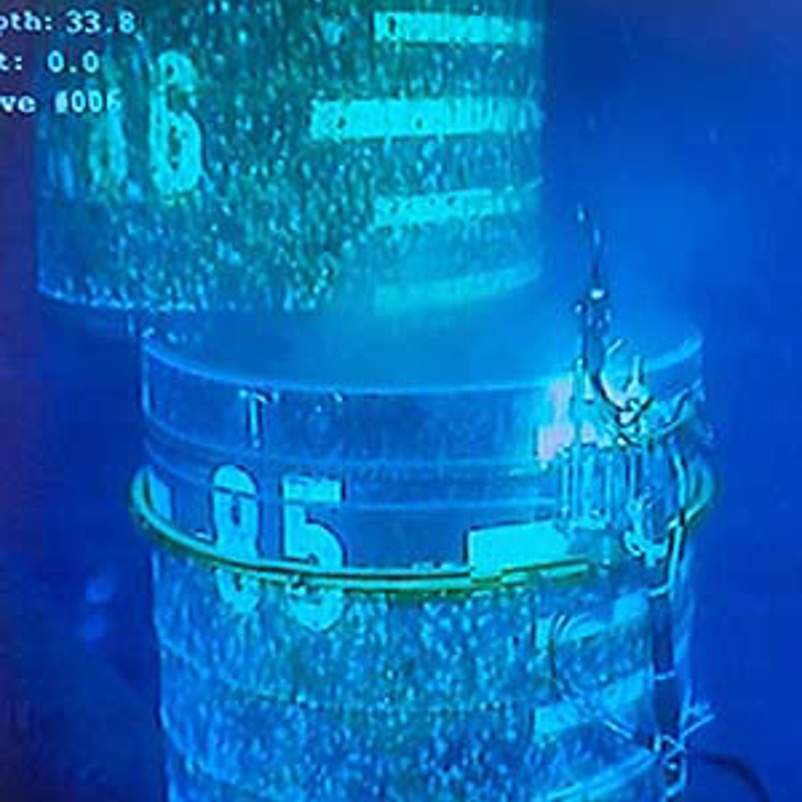

James Fisher Offshore’s ultra high-pressure abrasive water jet cutting system offers an innovative method for the internal cutting and removal of subsea tubular structures, ranging from piles and jacket legs through to well casings and well heads.

The abrasive cutting technology offers higher performance, cost savings and operational efficiencies to support the oil and gas industry's decommissioning cost reduction. Due to its higher accuracy and success rate, the system delivers enhanced performance with minimal downtime, as well as a reduced operational footprint.

A number of performance additions, including real-time cut verification, visual external cut monitoring and increased flexibility offer significant operational advantages. The unique airflow system negates the need to de-water and reduces the amount of operations in the task, minimising the equipment required, and leading to a 60 percent reduction in the overall cutting time. The cut verification system also ensures complete operator and customer certainty by helping to minimise the risk of stitching and, ultimately, reducing risk of over-run on high cost projects.

The advanced system has the additional capacity for external abrasive water jet cutting, suitable for subsea and topside applications. James Fisher Offshore can offer bespoke engineering and tailor the external cutting system to project specific requirements, helping to overcome obstacles that can render other cutting tools ineffective.

The James Fisher Offshore abrasive water jet cutting system is the most powerful and precise abrasive cutting system at 36,000psi, with a patented air surrounded jet. Using this cutting technology is typically 2.5 times faster and consumes less abrasive than traditional abrasive cutting methods.

Watch the Video.

Specification

Internal Cut and Lift Technology (ICLT), merges the JFO Abrasive Cutting system with a lifting tool, optimised with Ballgrab gripping technology, to provide a simple, flexible and quick mechanism to remove retired subsea assets and tubulars.

| Internal Cut and Lift Technology |

| ICLT (236 KB) |

| Abrasive Water Jet Cutting |

| Abrasive Water |